MMI is one of the largest company offering wide range of Ground Calcium Carbonates, Dolomite in domestic & export market.

Calcium carbonate or CaCO3 is found throughout the world and is one of the most commonly available minerals. In its natural form, it appears as chalk, limestone, & marble, dolomite. Although all three forms are identical in chemical terms, they differ in many other respects, including purity, whiteness, particle and uniformity. Calcium carbonate is one of the most useful and versatile materials known to man and wet and dry grinding methods are used in processing it for industrial applications.

The selected raw material has to be washed, crushed, fine grinded and then classified precisely to attain the products of exceptional consistent & desirable quality available in a variety of grades.

Mining

Calcium carbonate in one of the most commonly found minerals in nature and is available all over the world. We have control over large calcium carbonate deposits and depending upon our clients’ specifications, we can deliver upto 99.5% pure calcium carbonate with whiteness also ranging between 93% – 95%, hence making it one of the best materials available anywhere in the world.

Processing

Two processes are used to produce Ground Calcium Carbonate (GCC)

Dry ground calcium carbonate

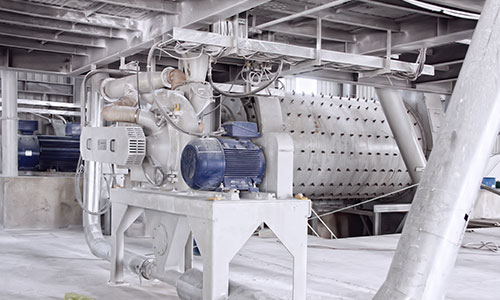

A dry process line (Ground calcium carbonate), involves a sequence of segregation, crushing and fine milling stages that produces a fine (micronized) product. During the processing, the material is processed & classified in dry form to attain the desired quality of the products as per customer /market requirements.

We are offering wide range of quality from mesh to micronized, Sub Microns –Nano calcium

Wet Grounded Calcium Carbonate

In the wet process (WGCC), the coarser powder materials obtain initially from dry process used as the raw material. The powder raw material prepared in slurry form after adding the suitable additive then made to pass through stages of wet attrition mills to get ultrafine product slurry with low viscosity of close PSD band. The slurry has The calcium carbonate slurry thus obtained is filtered & supplied through tankers & barrels or packed in dried form.

Features

- Controlled Particle Size

- High Purity

- High Brightness

- Innovative deep coating

- Consistancy

Calcium carbonate is the widely used mineral in the Paper filler & coating pigments, Plastics, Rubber & Elastomers, paints and coatings, adhesives and sealants industries both as filler and as a coating pigment. It is used widely used an extender and can represent as much as 30-45% by weight in paints. It is also one of the widest used filler in the production of master batches for the plastic industry.